Industrial Power Distribution Systems

Industrial power distribution systems form the backbone of modern facilities, supporting safe and reliable delivery of electrical energy across equipment and operations. Understanding how these systems are structured helps explain their role in maintaining continuity, reducing disruptions, and supporting efficient industrial workflows.

Industrial power distribution systems channel electricity from the utility or on‑site generation to diverse loads with the right voltage, protection, and control. A sound design balances safety, reliability, maintainability, and energy performance while remaining compliant with applicable codes and standards. In practice, that means coordinating equipment ratings, protection settings, conductor sizing, and documentation so that operations can continue with minimal risk and predictable maintenance windows.

Overview of industrial power distribution systems

A typical industrial network begins at the service entrance or substation, where medium‑voltage (MV) switchgear receives power from the utility or an internal microgrid. Power is then stepped down by transformers to low‑voltage (LV) levels for distribution via a main switchboard. From there, feeders supply panelboards, motor control centers, process equipment, and building systems. Depending on criticality, facilities may include double‑ended substations, ring main units, or spot networks that provide alternate power paths. Single‑line diagrams capture the overall topology, while detailed wiring diagrams show terminations, interlocks, and control wiring needed for safe operation and maintenance.

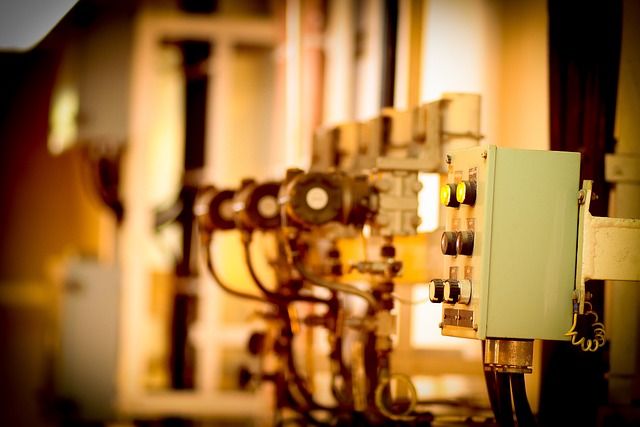

Key components used in facility power networks

Core elements shape performance and safety. MV and LV switchgear with appropriately rated circuit breakers or fused switches interrupt faults and isolate sections for work. Transformers match voltage to load requirements; options such as dry‑type or liquid‑filled designs are selected based on environment, efficiency, and fire safety. Bus duct (busway) and cable systems distribute high currents with compact routing, while trays and ladders protect conductors. Motor control centers (MCCs) organize starters, variable frequency drives (VFDs), and protective devices for process motors. Panelboards and power distribution units (PDUs) branch circuits to tools, IT gear, and lighting. Uninterruptible power supplies (UPS) and energy storage ride through short disturbances for sensitive loads. Generators with automatic transfer switches (ATS) or static transfer switches support continuity during outages. Grounding and bonding systems manage fault currents and stabilize voltages, and surge protective devices (SPDs) reduce transient overvoltage risk. Metering, relays, and supervisory systems provide visibility for operations and maintenance teams.

How power distribution supports operational reliability

Reliability is engineered through topology, protection, and maintainability. Redundant architectures—N, N+1, or 2N—limit single points of failure for critical processes. Selective coordination ensures that the device closest to a fault trips first, preventing a minor issue from cascading into site‑wide disruption. Proper short‑circuit ratings and arc‑flash mitigation features—such as current‑limiting devices, zone‑selective interlocking, maintenance switches, or arc‑resistant gear—help protect personnel and equipment. Maintenance bypasses and tie breakers enable work on transformers, UPS modules, or feeders without shutting down production lines. Condition‑based strategies, including infrared inspection, partial discharge testing, and continuous power quality monitoring, inform targeted interventions. Power quality controls like harmonic filtering, power factor correction, and voltage regulation stabilize sensitive instrumentation and variable‑speed drives.

Considerations for safe and efficient electrical layouts

Layout decisions influence safety, operability, and cost over the asset life. Provide clear working spaces, transport paths for heavy equipment, and separation from heat or moisture sources. Locate switchgear to minimize fault levels and conductor lengths while maintaining egress and ventilation. Apply appropriate earthing and bonding, manage touch and step potentials, and use labeling that supports lockout/tagout procedures. Cable routing should consider electromagnetic compatibility, segregation of control and power circuits, and thermal derating. For energy performance, right‑size transformers, select efficient motors, apply VFDs where load profiles benefit, and choose distribution voltages that balance losses against equipment availability. Plan for future growth with spare capacity in busway runs and panels, and include metering at meaningful points to track energy use and detect anomalies. Digital models, from single‑line diagrams to detailed wiring diagrams and BIM, help coordinate disciplines, reduce clashes, and maintain accurate as‑built records.

Overview of industrial power distribution systems

Design starts with understanding loads and their criticality. Classify processes by the consequence of downtime to determine where redundancy and ride‑through are justified. Map short‑circuit levels, voltage drop, and thermal limits to guide equipment selection and feeder sizing. Evaluate network configurations—radial for simplicity, ring for resilience, or double‑ended for continuity at substations. Where distributed energy resources or cogeneration are present, ensure protection schemes address reverse power flow and islanding behavior. Clear operating procedures, interlocks, and visible isolation points reduce human error during switching.

Key components used in facility power networks

Protection settings and device coordination are as important as hardware selection. Time‑current curves should be reviewed whenever loads change or new gear is added. Consider advanced relays that offer event logs, waveform capture, and IEC 61850 or Modbus integration for centralized monitoring. For MCCs and PDUs, modular withdrawable units can shorten maintenance windows. Where floor space is constrained, compact busway can reduce bends and splices compared to large cable bundles. In corrosive or hazardous areas, specify appropriate enclosures and ingress protection, and align with relevant classification standards. Document everything, from torque values to cable tags, so troubleshooting remains efficient throughout the system’s life.

How power distribution supports operational reliability

Operational reliability also depends on disciplined maintenance and change management. Establish inspection intervals for switchgear, breakers, relays, and protective earthing connections. Track breaker health via operation counts and trip unit diagnostics. Use thermal imaging to spot loose terminations, and schedule cleaning to control dust that can raise arc‑flash risk. Power quality analytics can correlate disturbances with production anomalies, guiding mitigation efforts. Finally, test emergency systems—UPS, generators, ATS/STS—under controlled conditions to confirm transfer performance and load acceptance without surprises.

Considerations for safe and efficient electrical layouts

Safety culture is reinforced by the physical environment. Provide adequate illumination, arc‑flash boundary markings, and clear labeling on feeders and equipment. Coordinate with fire protection and ventilation to manage heat from transformers, drives, and enclosures. Place monitoring points where operators can observe status without entering energized spaces. When expansions occur, revisit short‑circuit calculations, coordination studies, and documentation; revise the single‑line and wiring diagrams to reflect changes so that crews rely on accurate information during operations and maintenance.

In summary, industrial power distribution systems combine architecture, equipment, protection, and documentation to deliver safe, reliable, and efficient energy to processes and building services. Thoughtful choices in topology, component selection, protection coordination, and layout—supported by up‑to‑date single‑line and wiring diagrams—help facilities sustain uptime, manage risk, and control energy use over the long term.